Technologies & Product Features

V-Tech® V-Tech® is a complete protective membrane, designed with continuous microscopic pores, which allows heat vapor created on the inside to exit, while preventing water molecules from penetrating the garment.

Tri-Zone 3-in-1 The Viking Tri-Zone® 3 In 1 system garments are designed to maximize the usage of a single garment. You can wear the outer jacket as a stand alone waterproof, windproof shell or the inner jacket as a thermal layer. The jackets also feature a unique zipper that secures the two jackets together to form a waterproof insulated element barrier.

Trilobal PolyesterTrilobal Polyester utilizes triple twined polyester thread to create a cross section of fibres at regular intervals to form cells. These cells significantly increase the tensile strength of the garment over regular knit fabrics, effectively preventing tears from expanding to the next cell, while increasing the cut, tear and abrasion resistance of the garment.

100% Waterproof 100% waterproof designation relates to the garment fabric’s permeability to water in more extreme conditions. This garment is either made of a material that water cannot penetrate, or has a coating of PVC that water cannot penetrate. This garment is designed for uses in prolonged foul weather exposure. Products with PU (polyurethane) coatings may claim to be waterproof, however to the porous nature of PU water can penetrate the fabric where hydro-static pressure exceeds 11psi. Hydro static pressure increases with wind and the amount of water hitting the fabric. Wind storms where rain is being forced down at +25KPH will likely penetrate a PU coated rain garment.

Stormblaster®The Stormblaster® hood system reduces wind and rain exposure up the back of the jacket, while orienting the front close to the chin and cheek area. It has a safety “Tear Away” design, making it easy to remove and attach. Standard hoods are traditionally attached with hook-and-loop fasteners or buttons, leaving gaps that could allow water to travel up and around the neck area.

4-Way Stretch Waterproof/BreathableWaterproof/breathable 4-way stretch patented fabric moves with your body, offering unparalleled flexibility while keeping you dry and cool at the same time.

ThermoMaxx®ThermoMaxx® is a high-tech, ultra-thin and light weight insulation that provides maximum warmth without the bulkiness.

Temperature RatingsThroughout this catalogue, you will find suggested temperature ratings on ThermoMaxx® insulated garments or lined boots. These ratings were developed using the CLO value system of heat transfer between layers within a garment/boot, envisioning a mobile individual’s comfort level in these temperate zones. These ratings are for guidance purposes only.

Viking Jackets 101

WaterproofViking® uses the most globally recognized Hydrostatic Water Pressure testing method – AATCC 127 to qualify our fabrics as being waterproof. The test material is subjected to steadily increasing water pressure on one face until water penetration occurs on the opposite face in three separate locations. The minimum standard for Viking® is 11.2 psi (pounds per square inch) or 784 mbar. This may generically be called 8,000 waterproof.

Breathable Viking® uses the most globally recognized Water Vapour Transmission testing method – JIS L-1099 – Procedure B-1 to determine fabric breathability. This measures the ability of the fabrics to let steam or perspiration evaporate outside the textile. The test measures the amount of water in grams per sq. meter that migrates over a 24 hour period. Generally accepted ratings are listed in the adjacent table.

| 5,000 - 8,000 | g/m²/24hours |

| 8,000 - 15,000 | g/m²/24hours |

| 15,000+ | g/m²/24hours |

| = |

| = |

| = |

| Good Breathability |

| Very Good Breathability |

| Excellent Breathability |

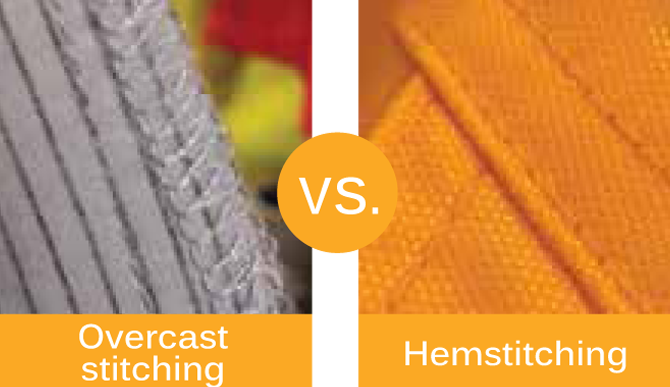

There are two common stitch types used in the outerwear market:

Hemstitching Fabric is folded over at the edge and the layers are stitched together. This provides a clean hem edge, and eliminates fraying threads. Hemstitching requires more time and quality attention to produce.

Overcast stitching This has a circular, continuous threading around the edge of the material. This system is much faster, and less expensive. The risk is that should this continuous thread break, the whole seam will unravel, also the fabric edge threads will “slip” pulling the trim stitching off the body of the fabric and commence unravelling

Double stitch vs. single stitch Double stitching joints increases the tensile resistance of the seam, while reducing the specific pressure on each stitch. Should one stitch get snagged and torn, the garment will not unravel. Polymer film garments should be stitched at seams as well as heat sealed to ensure stress points do not tear or peel. All Viking® garments are double stitched for durability.

Bar-tacking Bar-tacking is the reinforced repetitive stitching at critical tear points on a garment; these include pocket edges, arm and leg cuffs, button holes, and key stress areas in crotch, arm, and back.

All waterproof Viking® recreational garments have seams that are double sewn, taped, and heat sealed.

You can rely on Viking® gear to keep you safe, dry, and warm on the coldest and rainiest of days, because every part of the Viking® garment has been meticulously thought out to deliver a comprehensive waterproof system that is also comfortable to wear. Each component and the stitching behind a Viking® garment give you the protection you need to Brave The Elements®.

All Viking® garments are hemstitched and fully bar-tacked in all corners and stress areas.

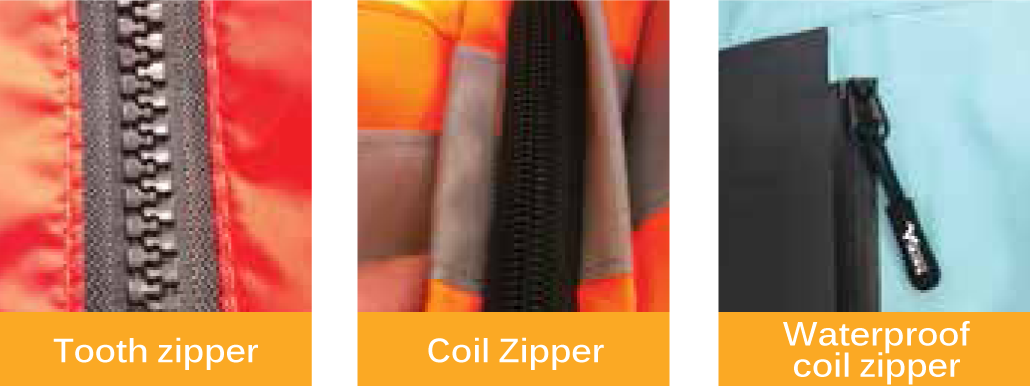

There are two common types of zippers used in outerwear:

Tooth ZippersThese are produced either in plastic or metal (brass). Tooth zippers offer the highest level of durability and longevity, and have the ability to withstand the torque of industrial and commercial uses. Highly recommended for front closures and boot zip regions.

Coil ZippersThese are considerably less expensive and are produced in plastic. Coil zippers are designed for low-pressure closures like pockets or arm vents. As front closures have a high risk of breaking or being damaged, tooth zippers are superior.

Embroidery access zippers

- Whether you are an ad specialty or a promotional business, Viking® recreational garments are B2B friendly with our 14" embroidery access zippers.

All Viking® garments use tooth zippers on front and boot closures